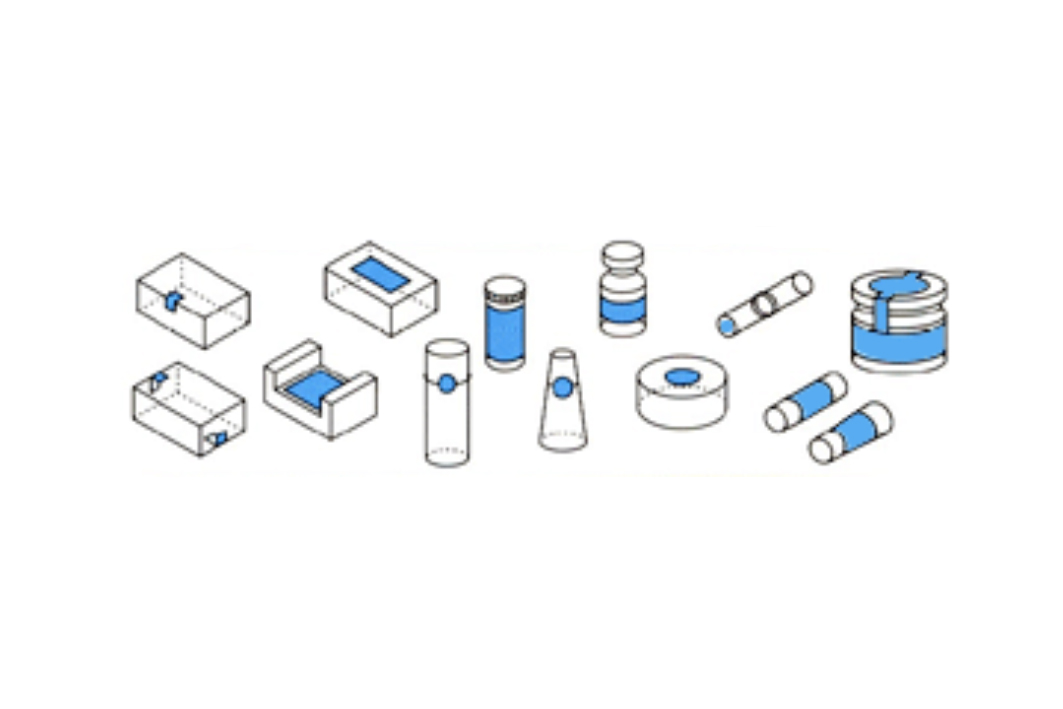

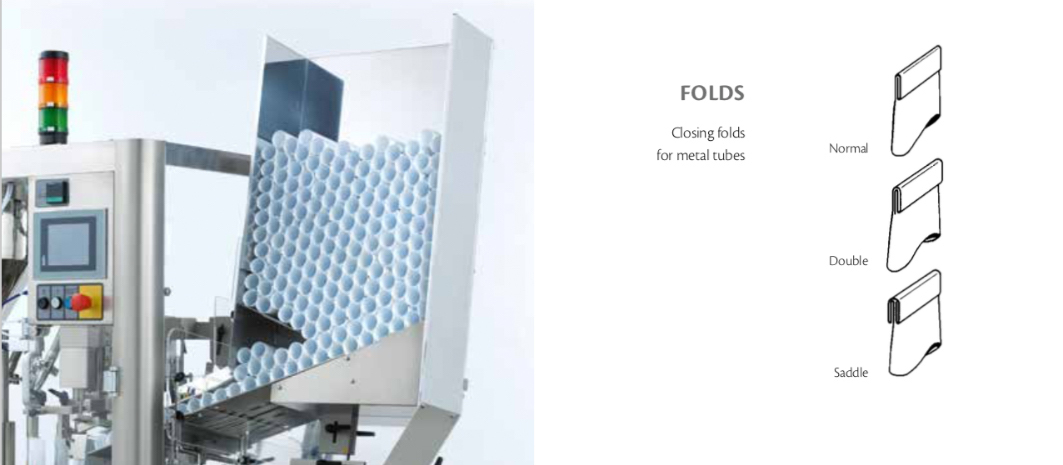

This machine completes product insertion, leaflet insertion and production batch & expiry date coding inone run. Also Equipped are malfunction warnings fo fail safe packaging processes. It is labor saving, suitable for pharmaceutincal, ointment or cream tubes, cosmetics, hardwares, stationary, etc.

A starwheel is equipped for bottle separating from each other and for precise loading on conveyer. It is only to replace a new stawheel for different bottle sizes.

To print manufacturing date, expiry date and batch numbers, a durable steel type wheel is adopted to emboss such information on carton.

By using a vacuum cup and a gripper, the leaflet is pushed precisely into the carton. The machine stops when there is no insert so as to avoid product mission with leaflet.

This is an automatic liquid filling machine of volumetric filling type, applicable in liquid of low viscosity. It is a straight-line system using pneumatic cylinders and other sensors with PLC control for bottle positioning and liquid filling without spillage and meeting cGMP requirement. It is easy in operation , short change-over time for different containers, thus very economical for one-machine-machine-multiple application operation. The automatic filling operation includes applications in chemical, pharmaceutical, food cosmetic and detergent industries.

It is easy in operation, can be changed to different volume of containers in a very short time without changing equipment.

It allows to adjustment of filling volume for all filling cylinders at the same time. Operation is quick and easy.

Filling pump adopts volumetric positive displacement design. SS#316L is used for liquid contact parts. Filling nozzles are equipped with drip free devices. During filling, bottles are clamped to allow precise insertion of nozzles. Simple in disassembly of filling components and ease in cleaning, meeting, meeting cGMP requirement.

It allows for minor adjustment of each filling cylinder to achieve fill volume accuracy of +/- 0.5 %.

This is a type of machine which is able to fill powder into bottle and to seal cap of the bottle. It is using the single piece machined rotating auger for filling of powder material into a container and subsequently at the capping station applying cap sealing operation. Good in looking. No powder spillage. Minimal damage to caps, meeting cGMP requirement are some of the features. It is suitable for western medicine powder, coffee powder, etc.

This machine is able to fill powder into bottles and seal caps of the bottles. It is suitable for powder materials such as granules, powder, chemicals, Chinese&Western medicine powder, coffee powder, etc.

The machine is equipped with dust detraction device to free machine from damages due to powder contamination. The stainless steel material hopper is esy to clean. Which minimizes cross-contamination

Theauger is single-piece machined for precision. Adopting auger for precise filling volume, filling is kept within +/- 1-3% weight variation, depending on powder physical characteristics. With a stirrer rotating in the material hopper, it ensures a smoother and more precise filling operation

This monoblock machine incorporates filling, pug insertion and over cap sealing functions. It is mainly used in small volume liquid packing applications.Being compact, minimal energy consumption, the machine is especially suitable for use inside a sterile area. With PLC and other photoelectric sensor controls, the filling, plug insertion & cap sealing operations are completed meeting cGMP requirement. It is suitable for eye drop, small volume liquid injectable, cosmetics, volatile oil packing applecations.

This machine is specially designed for small containers. It is used in small volume liquid packing operations.

It adopts high quality hygienic glass material for filling pumps. It allows for volume adjustment of one single cylinder or complete set of cylinders. It is using a universal joint in connection of cylinder and filling nozzle to minimize breakage. There is a photo sensor for bottle detection to achieve a goal of Bottle-Fill and No-Bottle-No-Fill

By using a mechanical arm with a jaw will allow the machine to insert the plug precisely into the bottle.

Pre-Screw capping device can place and pre-screw cap on bottle properly, it’s effectively avoiding cap-drop during moving. Before placing and pre-screw cap on bottle, a photo sensor detects the availability of plug. It avoids bottle without plugs.

There is a bottle clasping device at the sealing station, while the sealing head equipped with adjustable torque as needed for individual cap & bottle, in addition to tension absorbing mechanism to extend sealing durability. It is easy in bottle size shange-over for different bottle cap size

The sealing head is a sealing roller design, possible for adjustment of cap sealing tightness without affecting smooth appearance of caps It is easy in bottle size chnge-over for different bottle cap sizes.

By using a mechanical arm to pick up the cap, place it under sealing head, precisely place it on top of bottle b the sealing head, this process. Ensures a very smooth and exact sealing operation. The sealing head is slso equippe with adjustable torque as needed for individual cap & bottle, in addition to d tension absorbing mechanism to extend sealing durability. It is easy in bottle size change-over for different bottle cap sizes.

This machine delivers label, gummed with resinous glue, from turret to vacuum belt and from belt to the bottle surface. It is possible to quickly exchange different bottle and label sizes with ease. It is simple in

This machine delivers label, gummed with resinous glue, from turret to vacuum belt and from belt to the bottle surface. It is possible to quickly exchange different bottle and label sizes with ease. It is simple in operation, neat, easy to clean up and suitable for round container labeling applications in industries, such as chemical, pharmaceutical, food, winery, etc.

It is especially designed for round container labeling applications.

The label is hold-up on its back side by a blower/vacuum system and is precisely and smoothly. Pressed on bottle. Standard no-bottle-no-label mechanism is ensured with a photo sensor control.

It is in a simple design for ease of operation, cleaning and maintenance.

The machine is designed for containers of various forms. Being good looking, not damaging bottles and meeting cGMP requirement, it is easy in operation, short change-over time for different container and caps, thus very economical for one-machine-multiple application operation. These automatic capping operations include apptions in chemical, pharmaceutical, food, cosmeic and detergent industries.

Automatic Cap sealing Machine is suitable for different containers and caps.

The sealing head is a sealing roller, possible for adjustment of cap sealing tightness without affecting smooth appearance of caps. It is easy in bottle size change-over for different bottle cap sizes.

By using a mechanical arm to pick up the cap, place it under sealing head, precisely place it on top of bottle by the sealing head, this process ensures a very smooth and exact sealing operation. The sealing head is also equipped with adjustable torque as needed for individual cap & bottle, in addition to tension absorbing mechanism to extend sealing durability. It is easy in bottle size change-over for different bottle cap sizes.

It is a rotary, multi-sealing head design for faster sealing operation to meet customer’ high volume requirement.

Specifications |

|

| Machine Speed | Max. 50 strokes/min. |

| Cavity Depth | Max. 10mm |

| Available Forming Area | DK-PS 30A / 40A / 40AL / 40AXL DK-PS 3000A / 4000A / 4000AL / 4000AXL |

With following features, your production is EASY & EFFICIENT:

You BENEFIT the advantages of our intermittent platen sealing system:

The standard Flow wrapping machine with Rotary motion Sealing for high speed running and cost effective packaging, to pack the product with film in roll and 3 side sealed pillow pack, could be with different level control system and accessories for different requirement.

Provide 20 – 250 PPM according to the configuration and products condition.